- Agricultural machinery

- Aspirator, obezprashiteli, dust extractors, filters

- Automation, production lines

- Belt conveyors

- Cleaning machines

- Compressors, pneumatic, generators

- Construction equipment service

- Construction equipment, earth moving equipment

- Cranes, tower cranes

- Cutting Tools

- Electric and coils

- Elevators, eskalatori, elevators, lifts

- Fire Equipment

- Furnaces, industrial boilers, ovens, dryers

- Garden equipment

- Hand Tools

- Hydraulic Machines

- Kitchen Equipment, Restaurant Equipment

- Lifting equipment, trucks, forklifts, elevators, trolleys

- Lifts, cableways, ski lifts

- Machinery for garment industry

- Machinery for pulp and paper

- Machines for food industry

- Machines for plastics processing, injection-forms

- Machines for the chemical industry

- Machines for the Footwear Industry

- Machines for the furniture industry

- Machines for the pharmaceutical industry

- Machines for the textile industry

- Machines for windows

- Machines for Wood

- Manufacturing

- Metalworking Machines

- Mining Equipment

- Other machines

- Packing, packaging and processing equipment

- Polygraphic and printing equipmen

- Power tools

- Pumps, vacuum pumps, pump, pumping stations

- Refrigeration, cabinets, vending - vending machines

- Road Construction equipment and spare parts

- Spare parts for machines

- Stone processing machines

- Towers, Autotowers

- Ventilation

- Welding equipment and consumables

Последни новини

Manev - WW

| PRODUCTS |

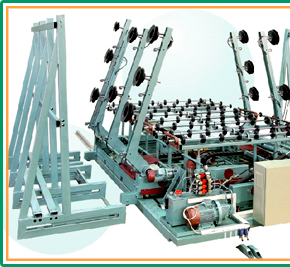

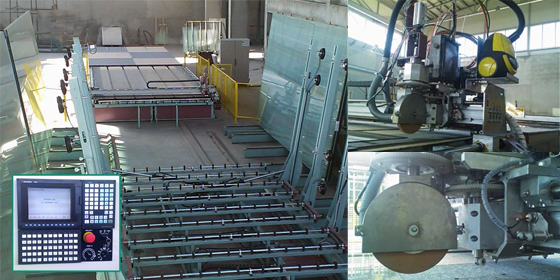

| UNLOADING DECK ASSEMBLY RK – S/D/SM/DM - NEW! |

This fully automated system has been designed for two-way picking up of the raw glass pane ingots from the glass storage racking.

The glass is picked up for processing following preliminary selection of the operation from the RK control panel or on the basis of data supplied by the process sequence monitoring system (optimization).

The system is equipped with a transportation device (longitudinal travel), which allows picking up of the raw glass pane ingots one after another from two rows of glass storage locations (pyramids).

Mounted on the chassis are a hydraulic aggregate and a vacuum pump. The hydraulic aggregate feeds the prescribed oil pressure to the outgoing trolley, respectively the rotating frames. The vacuum pump provides the necessary vacuum for the suction units, which help lift the glass panes. The two rotating frames with the girdles of the suction units run on bearings in the chassis and are driven by hydraulic cylinders.

This station for fitting glass panes is equipped with a separation fixture.

The separation fixture guarantees that sticking together glass panes can be released and lifted. The separation fixture, however, is applicable and necessary only in the case of large size panes. The transportation rollers are put in motion by means of a chain gear and an electric motor fixed to the bottom side of the swivel-mounted frame.

The operation process is controlled by end cut-out switches located at different places. By means of selection on the RK control panel three different sizes of glass pane ingots may be loaded for processing.

| MASHINE TYPE | PK-S/M | PK-D/M |

| Max glass sizes Min glass sizes Glass pane thickness Loading depth Unloading positions Height Unloading time |

2750х3810 mm 1750х2000 mm 2 - 12 mm 600 mm 1 - 8 970* mm 3 min |

3300х6000 mm - 4 - 10 mm 1200 mm 2 - 6 970* mm 3 min |

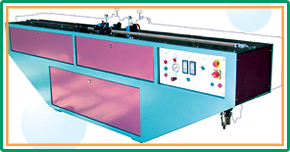

| CUT TABLE |

|

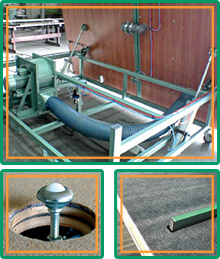

Shearing table for flat glass with pneumatic drive

|

| ROLLING PRESS |

The pneumatic vertical rolling press guarantees even pressing down of the glass package along its length to the required thickness.

| The equipment comprises the following major assemblies: - Feeder-conveyor with lamps - Harmonious working capability washing mashine vertical press and tilt table - Clamping rubber rollers with pneumatic drive - Photo-sensor for automatic cycle control - Controller - Outlet transporter |

|

| Technical specifications | |

| Air consumption rate Speed Installed power Length Width Height |

100 2,5 m/min 1,5 kW 4000 - 6000 mm 1100 mm 1600 mm; 2200 mm |

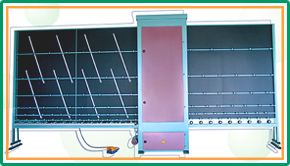

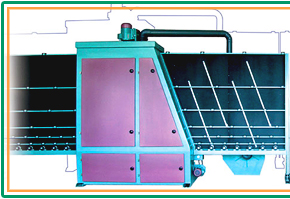

| VERTICAL GLASS-PACK WASHING MACHINE - Vmm S 1,6/2 |

|

Technical characteristic: - Low labour costs - High productivity - No expensive chemicals for rinsing - Universality and multi-variability - Problem-free integration into semi-automatic lines - Guaranteed drop-free antistatic rinsing irrespective of the hardness of the used water - Stainless steel washing units |

| Technical specifications | |

| Rinsing height Glass pane thickness Rinsing speed Installed power Number of brushes Water consumption rate Demineralizer capacity Length Width Height |

1600 mm (open air) 3 - 10 mm (1,7) m/min 9 kW 2 120 l/day 360 l/day 5200 mm 1100 mm 2800 mm |

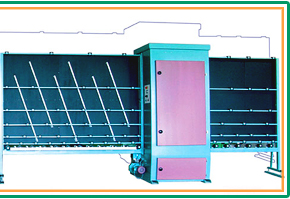

| VERTICAL GLASS-PACK WASHING MACHINE - Vmm S 1,6/4 |

| Technical characteristic: - Low labour costs - High productivity - No expensive chemicals for rinsing - Universality and multi-variability - Problem-free integration into semi-automatic lines - Guaranteed drop-free antistatic rinsing irrespective of the hardness of the used water - Stainless steel washing units - The washing sensibility of coated glass |

|

| Technical specifications | |

| Rinsing height Glass pane thickness Rinsing speed Installed power Number of brushes Water consumption rate Demineralizer capacity Length Width Height |

1600 mm (open air) 3 - 10 mm 0 - 3,5 m/min 10 kW 4 120 l/day 360 l/day 5500 mm 1100 mm 2800 mm |

| VERTICAL GLASS-PACK WASHING MACHINE - Vmm S 2,2/4 |

Technical characteristic:

|

- Low labour costs - High productivity - No expensive chemicals for rinsing - Universality and multi-variability - Problem-free integration into semi-automatic lines - Guaranteed drop-free antistatic rinsing irrespective of the hardness of the used water - Stainless steel washing units - The washing sensibility of coated glass |

| Technical specifications | |

| Rinsing height Glass pane thickness Rinsing speed Installed power Number of brushes Water consumption rate Demineralizer capacity Length Width Height |

2200 mm 3 - 10 mm 0 - 3,5 m/min 14 kW 4 - 8 200 l/day 360 l/day 7000 mm 1100 mm 3400 mm |

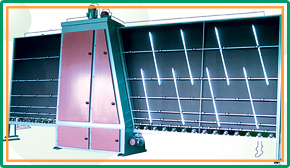

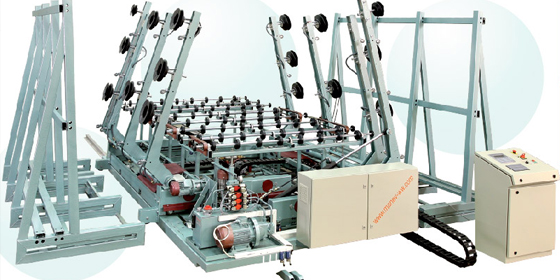

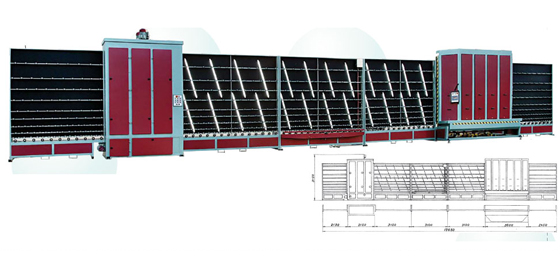

| VERTICAL DOUBLE GLASSLINE - VLS 2,2 |

| - Stainless steel washing units - 4-8 washing brushes - The washing sensibility of coated glass - Air fun (Ventilator) with capacity of 6000 m3/min - Washing water purification system - Working direction from left to right - Monitored washing control - Combining two glasses manualy |

|

- Harmonious working capability washing mashine vertical press and tilt table

- Vertical press with couple rubber rollers

- Working in automatic between the thickness from 10 mm to 40 mm

- Pneumatic sinking plot with follow-up horizontal transportation of the glass package

| Technical specifications | |

| Voltage Frequency Installed power Air pressure Air consumption rate Length Width Height Weight Noise emission Washable glass sizes: Length Height |

380 V 50 Hz 17 kW 6 bar 150 L/min 14 300 mm 2 300 mm 3 400 mm 2800 kg 90 dB (A) 350-3210 mm 100-2200 mm |

| VERTICAL DOUBLE GLASSLINE -VLS 1,6 |

- Stainless steel washing units

- 4-8 washing brushes

- The washing sensibility of coated glass

- Air fun (Ventilator) with capacity of 6000 m3/min

- Washing water purification system

- Working direction from left to right

- Monitored washing control

- Combining two glasses manualy

- Harmonious working capability washing mashine vertical press and tilt table

- Vertical press with couple rubber rollers

- Working in automatic between the thickness from 10 mm to 40 mm

| Technical specifications | |

| Voltage Frequency Installed power Air pressure Air consumption rate Length Width Height Weight Noise emission Washable glass sizes: Length Height |

380 V 50 Hz 10 kW 6 bar 100 L/min 11 000 mm 1 100 mm 2 800 mm 2 600 kg 90 dB (A) 350-3210 mm 100-1600 mm |

| SCROLLING TABLE |

|

|

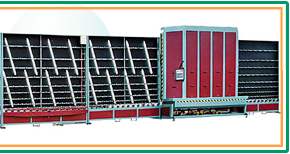

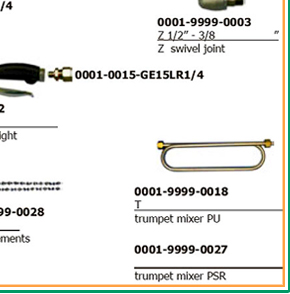

| VERTICAL LINE FOR INSULATING GLASS UNIT PRODUCTION WITH AN AUTOMATED PANEL PRESS |

High-quality and high-efficiency manufacturing of IG Units with servo motor technology

- Left-to-right working direction

- Automatic speed adjustment at carrier wheels

- The washing machine is equipped with a washing section, a rinsing section and a drying section, separated by stainless-steel partition screens;

- Automated demineralizer;

- Stainless steel water tank;

- Illuminated control system after the washing unit

- Possibility for automated manufacturing of double and triple IG units

- Possibility for automated production of all types of flat “structural glazing”

- Surface protection system with air flow

- Touch screen control

- Possibility for selecting an automated or manual work mode

- Thickness control of the IG unit in 4 (four) different points

- A “hot-line” service for the line operation control

- Possibility for generating a “service” clearance of 500 mm between the two panels

| Options: |

| - Height of IG unit – 1600 mm; 2250 mm; 2500 mm - Number of brushes – 4; 6; 8 brushes Optional equipment: - Tilt conveyor table after the press unit - Horizontal roll conveyor table for the IG unit - Additional vertical conveyor between the assembly table and the panel press. |

| BUTYL EXTRUDER |

The Butyl Extruder Model BE-7000 of 7 kg capacity is used to apply the first butyl sealing onto the aluminium frames of the double-sealing panes of insulating glass.

Its specific characteristics are:

| - A belt conveyor which shifts the frame with uniform motion at variable speed (0 to 30 m.p.min.) - Synchronized opening-closing of the nozzles spraying the butyl and weels which block the frame on the belt conveyor - Opening of nozzles from 5 mm to 29 mm - Electronic thermostats-programmed or manual starting - Opportunities to regulate the butyl flowing rate |

|

| Technical specifications | |

| Voltage Frequency Air consumption Max. hydraulic pressure Installed power Length Width Height Weight |

380 V 50 Hz 20 L/min 200 bar 4,5 kW 3 100 mm 470 mm 1000 mm 460 kg |

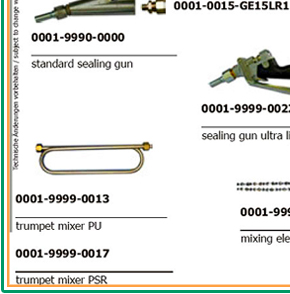

| SPARE PARTS |

|

| FEEDBACK FORM |

| I would like to receive more information about: |

Video from Manev - WW

ПАДАЩ ТРАНСПОРТЬОР - video 1

amr cut - video 2

amr clean - video 3

Send mail to company Manev - WW

If you send advertising or other communications provided by you or any third party goods or services to Manev - WW will be considered unsolicited commercial messages. Sending such messages is prohibited by law and constitutes a violation of Bulgarian law and the Terms of BUSINESS.bg.

Report inaccuracy in information of: Manev - WW

Последни новини

- Agricultural machinery

- Aspirator, obezprashiteli, dust extractors, filters

- Automation, production lines

- Belt conveyors

- Cleaning machines

- Compressors, pneumatic, generators

- Construction equipment service

- Construction equipment, earth moving equipment

- Cranes, tower cranes

- Cutting Tools

- Electric and coils

- Elevators, eskalatori, elevators, lifts

- Fire Equipment

- Furnaces, industrial boilers, ovens, dryers

- Garden equipment

- Hand Tools

- Hydraulic Machines

- Kitchen Equipment, Restaurant Equipment

- Lifting equipment, trucks, forklifts, elevators, trolleys

- Lifts, cableways, ski lifts

- Machinery for garment industry

- Machinery for pulp and paper

- Machines for food industry

- Machines for plastics processing, injection-forms

- Machines for the chemical industry

- Machines for the Footwear Industry

- Machines for the furniture industry

- Machines for the pharmaceutical industry

- Machines for the textile industry

- Machines for windows

- Machines for Wood

- Manufacturing

- Metalworking Machines

- Mining Equipment

- Other machines

- Packing, packaging and processing equipment

- Polygraphic and printing equipmen

- Power tools

- Pumps, vacuum pumps, pump, pumping stations

- Refrigeration, cabinets, vending - vending machines

- Road Construction equipment and spare parts

- Spare parts for machines

- Stone processing machines

- Towers, Autotowers

- Ventilation

- Welding equipment and consumables